Direct to Garment (DTG) T-Shirt printing or digital T-Shirt printing is the process of printing full-colour images onto garments. DTG can be used on light or dark colored garments. Using the latest printing technology and top quality DTG machines, we can print full-colour images onto a wide range of T-Shirts, polo shirts, hoodies and other clothing.

Sinocolor System. Much more professional and more stable than desktop modified printer. Control the color freely.

Dual Epson Heads equipped. Achieve real fast speed printing.

Built with dual-pallet. Effectively improve the work efficiency

One-time mold aluminum carriage beam. Ensure high accuracy of carriage movement.

High grade two-layer Germany Igus drag chain. Effectively protect ink tube and cables.

Taiwan Hiwin steel guide rail. Build for long life use.

Screw drive transmission and dual Y-Axis guide rail are equipped to guarantee the high precision printing.

White ink circulation equipped. That can collect and filter the ink from capping unit. Then flow back to ink bottle and reuse. Greatly reduce the waste of white ink. Save much running cost.

Besides, White ink stir system is equipped. Reduce problem caused by White ink precipitation.

Low ink alarm is equipped to protect the printer.

Well-designed touch screen. Easily adjust platform position and do the cleaning.

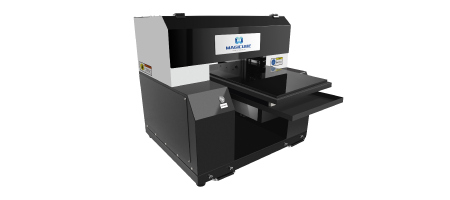

High-end and Modern design. Enhance the image of the company.

Application

Direct to Garment (DTG) T-Shirt printing or digital T-Shirt printing is the process of printing full-colour images onto garments. DTG can be used on light or dark colored garments. Using the latest printing technology and top quality DTG machines, we can print full-colour images onto a wide range of T-Shirts, polo shirts, hoodies and other clothing.

| Model No. | TP-600D Plus | |

| Print Head | 2X Epson i1600 printhead | |

| Print Resolution | 2400 dpi | |

| Printing Speed | 1 minutes for one t-shirt | |

| Print Head Adjustable Height | 5 cm MAX | |

| Printing Size | 2 pcs 30 x 40 cm Pallet | |

| Print Direction | Intellingence double side | |

| Height Adjust | Electric | |

| Print Method | micro piezo print technology,intelligence drops transformation technology | |

| Distance of Print Head Printing | 1-3 mm (2 mm is the best) | |

| Ink Color | 4 colors (CMYK) or 5 colors (CMYK,W) | |

| Ink Supply System | CISS | |

| Ink Consumption | 15-20 ml / squre meter | |

| Min Ink Drop Size | < 1.5 PL | |

| Interface | USB 3.0 | |

| Rip Software | Maintop(Standard)/ FlexiPrint (Optional) | |

| Normal Working Environment | Temperature 18-30 Celsius, Humidity 30-70 RH, Clean room, Low dust, Less sun light | |

| Power | AC 110/ 220V, 50/ 60Hz, 300W | |

| Size&Weight | Machine | L1730*W1110*H680mm, 280KG |

| Packing | L1840*W1190*H840 mm, 400KG | |

Application